As the demand for efficient and high-quality printing solutions continues to rise, choosing the right Thermal Printing Paper becomes increasingly critical for businesses and industries alike. According to a report by Smithers Pira, the global market for Thermal Printing Paper is projected to grow to $7.2 billion by 2025, driven by advancements in printing technology and sustained growth in sectors such as retail, logistics, and healthcare. This significant market expansion emphasizes the importance of selecting the best options available to meet specific printing needs and ensure optimal performance.

Industry experts, like Dr. Emily Lawson, a leading analyst in the printing materials sector, underscore the importance of quality in Thermal Printing Paper. She states, "Selecting superior Thermal Printing Paper is essential not only for print clarity but also for the longevity and durability of printed materials." With various types of thermal papers available, including direct thermal and thermal transfer, understanding the differences and applications of each type is fundamental for users looking to enhance their printing capabilities. This article will explore the top Thermal Printing Paper options for 2025, aiding businesses in making informed decisions tailored to their precise requirements.

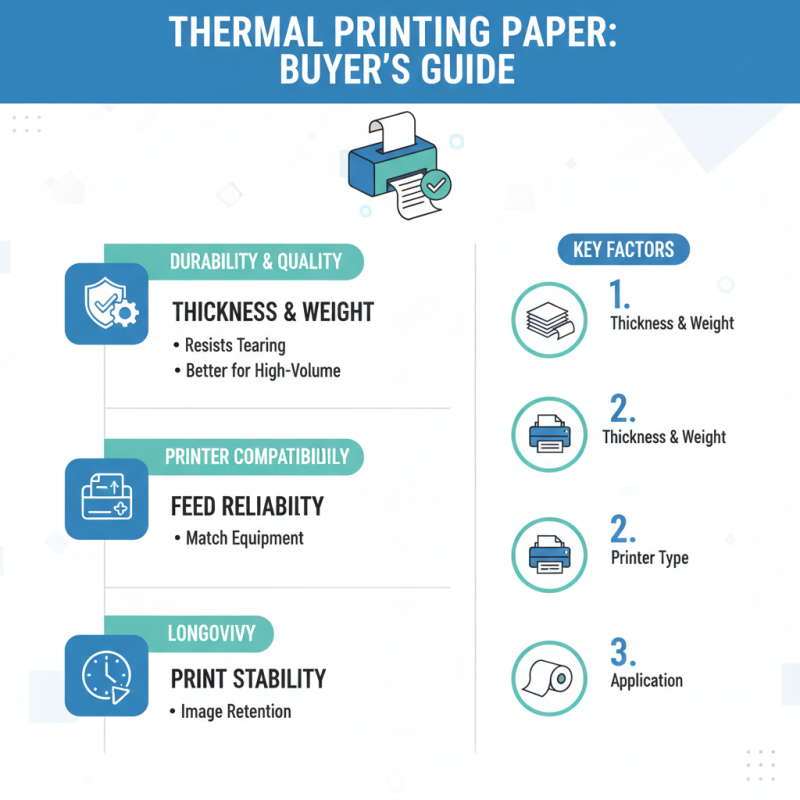

When selecting thermal printing paper, several key factors should be taken into account to ensure you choose the best option for your specific needs. One of the primary considerations is the paper's thickness and weight, which can affect durability and print quality. Thicker paper generally provides better resistance to tearing and damage, making it suitable for high-volume printing environments where longevity is essential. Additionally, the weight of the paper can influence how well it feeds through the printer, so it's essential to select a weight compatible with your equipment.

Another crucial aspect to consider is the coating of the thermal paper. Different coatings can affect the printing process, including heat sensitivity and image quality. For instance, some papers are designed for high-contrast images, while others may be better suited for everyday printing tasks. It's also important to think about the intended use of the printed materials; whether it is for receipts, labels, or tickets can significantly impact the choice of coating and paper type. Lastly, environmental factors play a role as well, with options available that are more environmentally friendly, such as those made from recycled materials or with reduced chemical content, catering to businesses looking to minimize their ecological footprint.

In 2025, the landscape of thermal printing paper offers a variety of options tailored to meet diverse printing needs. One of the most common types is direct thermal paper, which utilizes heat-sensitive coating to produce images. This paper is favored in settings like retail and shipping, where quick, high-quality labels are essential. Its ease of use eliminates the need for ink or ribbons, making it an economical choice for businesses focused on efficiency.

Another notable type is thermal transfer paper, which is used in conjunction with a ribbon to create durable and long-lasting prints. This type is particularly useful for industries requiring robust labels, such as warehousing and manufacturing, where products may be exposed to harsh conditions. Additionally, specialty thermal papers, such as those with water-resistant or UV-resistant coatings, are available, addressing specific requirements in niche markets. When choosing thermal printing paper, understanding these various types and their applications will ensure that users select the best option for their operational needs in 2025.

When selecting the ideal thermal printing paper for 2025, it is essential to evaluate key brands that dominate the market. Industry reports indicate that the global thermal printing paper market is expected to grow at a CAGR of around 6% over the next few years, driven by increased demand in retail sectors and logistics operations. A comparative review of leading brands reveals significant variances in paper quality, price point, and environmental impact, which can influence purchasing decisions for businesses.

In comparing the top brands, several parameters come into focus; thermal sensitivity, durability, and surface characteristics are paramount. Thermal sensitivity ensures that prints appear clearly, while durability plays a crucial role in how well the prints withstand environmental factors and wear and tear. Brands typically range from budget options that prioritize cost-effectiveness but may compromise on quality, to premium options that offer high durability and superior print fidelity. Reports indicate that businesses often see a 20% increase in operational efficiency when utilizing higher-quality thermal printing paper, reflecting the importance of making informed choices in this area. Evaluating these features against your specific printing needs can help in making the best selection to enhance productivity and reduce costs.

Thermal printing paper is increasingly finding its place across various industries due to its efficiency and versatility. In retail environments, such as grocery stores and clothing outlets, thermal printing paper is often used for receipts. This type of printing enhances the checkout process, allowing faster transactions while providing customers with clear, durable receipts. Additionally, point-of-sale systems equipped with thermal printers can generate high-quality labels for inventory management, improving stock accuracy and sales tracking.

In the logistics and transportation sectors, thermal printing paper is critical for generating shipping labels and barcodes. The durability of thermal prints ensures that labels can withstand handling and environmental conditions during transit. Moreover, thermal printing is crucial in healthcare settings, where accurate labeling of medication and patient records is essential. Using thermal printing paper for wristbands and medication labels enhances patient safety and service efficiency, making processes clearer and more reliable. As industries continue to innovate, the applications of thermal printing paper will expand, making it a pivotal component in various workflows.

Sustainability is becoming a crucial focal point for industries around the globe, and the thermal printing paper sector is no exception. As businesses strive to reduce their ecological footprints, opting for eco-friendly thermal printing paper has emerged as a responsible choice. According to a report by Smithers Pira, the global demand for sustainable paper products is projected to grow significantly, with eco-friendly paper expected to account for over 50% of the market by 2026. This shift not only aligns with corporate social responsibility objectives but also meets increasing consumer demand for environmentally considerate products.

Recent innovations in thermal printing paper have introduced options made from recycled materials and those that are chlorine-free and BPA-free. These advancements significantly minimize harmful effects on both human health and the environment. A study published by the Environmental Paper Network highlights that utilizing recycled materials can reduce energy consumption by 40% and water use by 50%. Moreover, companies are beginning to embrace compostable thermal papers that break down naturally and contribute to soil health, promoting a circular economy model. Such alternatives are essential for businesses committed to sustainability while still requiring reliable and effective printing solutions.