Thermal Coating Paper is a revolutionary material that combines the principles of thermal transfer with high-quality paper, providing an array of applications across various industries. According to a recent industry report from Smithers Pira, the thermal paper market is projected to grow at a CAGR of 5.1% from 2021 to 2026, driven primarily by the increasing demand for point-of-sale applications and labels. This growth highlights the significance of Thermal Coating Paper as businesses seek efficient, reliable, and eco-friendly solutions.

Dr. Emily Chen, an expert in the field of material science at the Institute of Paper Chemistry, emphasizes the transformative potential of Thermal Coating Paper, stating, “As technology evolves, the adaptability of thermal coating materials reshapes the way we approach printing and packaging.” This sentiment underscores the importance of understanding not just the mechanics of Thermal Coating Paper, but also its applications in sectors ranging from retail to healthcare, where immediate output and durability are paramount.

Understanding the underlying technology and numerous applications of Thermal Coating Paper is essential for stakeholders aiming to stay ahead in this competitive market. From improving the efficiency of thermal printers to ensuring high-quality output in demanding environments, the role of Thermal Coating Paper is increasingly vital in today’s fast-paced commercial landscape.

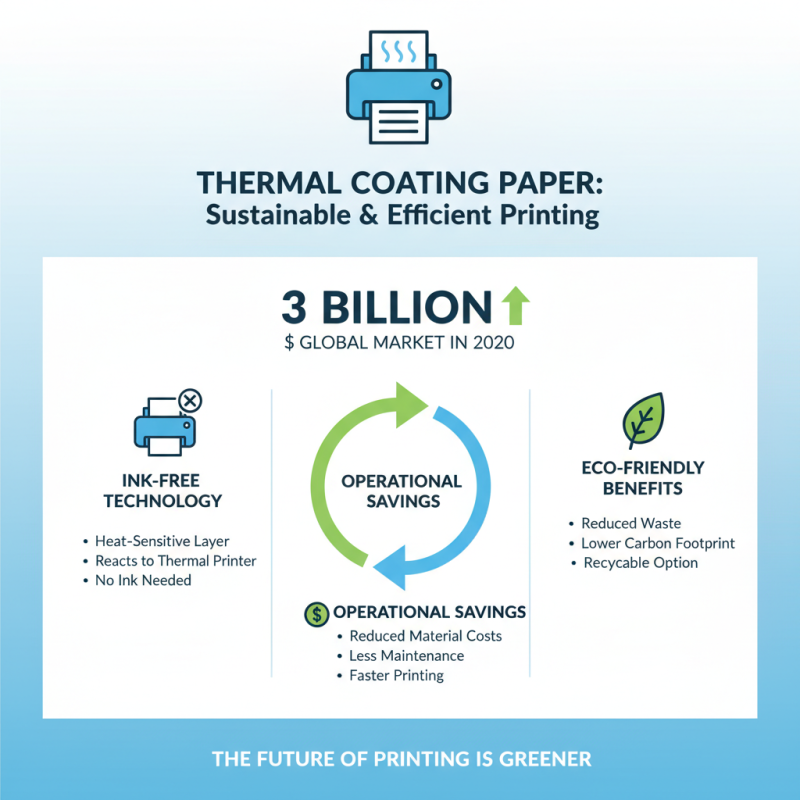

Thermal coating paper is a specialized paper that is treated with a heat-sensitive layer, enabling it to react to heat from a thermal printer. This technology eliminates the need for ink, making thermal coating paper a sustainable and efficient option across various industries. According to a report by Smithers Pira, the global thermal paper market was valued at approximately $3 billion in 2020 and is expected to grow as businesses seek eco-friendly solutions that also reduce operational costs.

The mechanism of thermal coating paper involves a coating that changes color when exposed to specific heat levels. As the thermal print head of the printer comes into contact with the paper, it generates heat, triggering a chemical reaction in the coating that results in the formation of a visible image. This process is particularly favored in sectors such as retail and logistics, where high-speed printing and efficiency are paramount. Data from the International Journal of Science and Research indicates that the demand for thermal paper is expected to rise due to its applications in receipts, labels, and tickets, reinforcing its importance in modern commerce and communication practices.

Thermal coating technology is a remarkable process that enables the creation of specialized papers capable of transferring images or text without the use of ink. At the heart of this technology is a thermal coating layer made from a mixture of chemicals that react to heat. When activated by a thermal printing head, these coatings undergo a chemical change, resulting in a ranging of colors that form visible patterns. This method is celebrated for its precision and efficiency, contributing to the rapid pace of both commercial and industrial printing applications. According to the latest market research, the global thermal paper market reached approximately 3.4 billion USD in 2022, and is projected to maintain a CAGR of around 4.5% through 2028.

One of the most interesting aspects of thermal coating technology is its versatility across numerous applications. It is not limited to retail receipts but also extends to labels, tickets, and medical charts. A study conducted by industry analysts highlights that around 62% of end-users in the point-of-sale segment favor thermal paper due to its ability to produce high-quality prints swiftly, without the hassle of replacing ink cartridges. Furthermore, advancements in thermal coating processes are leading to environmentally friendly alternatives, as many manufacturers are exploring the use of recycled materials and safer chemical compositions. This evolution not only caters to the increasing consumer demand for sustainable products but also aligns with regulatory efforts aimed at reducing environmental impact.

Thermal coating paper is an essential material used in various applications due to its unique properties. It primarily serves in industries requiring quick and efficient printing solutions. One of the most common uses of thermal coating paper is in point-of-sale (POS) systems, where it facilitates the rapid production of receipts. According to a report by Smithers Pira, the global market for thermal paper is expected to grow at a CAGR of 4.3% from 2021 to 2026, highlighting its significance in modern retail and service transactions. Additionally, thermal coating paper is widely utilized in the production of labels, tickets, and tags, offering businesses a reliable option for high-quality printing that resists smudging and fading.

Another notable application is in the medical field, where thermal paper is used for printing patient records and lab results. This is particularly important for preserving the quality and legibility of vital information. The healthcare sector relies heavily on various types of thermal papers, given their efficiency in providing quick printouts for critical documents. Furthermore, thermal coating paper is gaining traction in the logistics industry for shipping labels due to its ability to withstand varying environmental conditions.

Tips: When selecting thermal coating paper, consider factors such as thermal sensitivity and compatibility with your printing technology. Additionally, storing thermal paper in a cool, dry place can significantly extend its shelf life and ensure optimal performance.

Thermal coating paper is increasingly gaining traction across various industries due to its unique advantages. One of the primary benefits is its efficiency in printing and processing. The thermal coating allows for rapid temperature changes, which enables quicker printing speeds and reduces processing times compared to traditional paper types. This feature is particularly advantageous in high-demand environments, such as retail and logistics, where immediate receipt issuance or label printing is crucial for operations.

Another significant advantage is its durability and resistance to environmental factors. Thermal coating paper provides enhanced protection against moisture, chemicals, and UV rays, making it ideal for outdoor use and challenging conditions. Industries such as food and beverage, logistics, and healthcare benefit from this resilience, as it ensures that printed information remains legible and intact over time.

Moreover, the eco-friendly aspects of thermal coating paper, often utilizing less ink and generating less waste, align with the growing emphasis on sustainability within modern business practices.

The environmental impact of thermal coating paper is a critical topic as industries increasingly rely on electronic paper rolls for printing receipts, labels, and various applications. Typically coated with a mixture of chemicals that react to heat, thermal coating paper eliminates the need for ink, reducing waste generated from traditional printing methods. However, the production and disposal of thermal coating paper raise several environmental concerns.

The manufacturing process of thermal coating paper consumes energy and raw materials, contributing to carbon emissions and resource depletion. Moreover, many thermal papers contain phenol and bisphenol A (BPA), which are harmful chemicals that can leach into the environment. The presence of these toxic substances in landfill sites poses risks to soil and water quality, negatively impacting ecosystems. As industries adopt more sustainable practices, there is a growing demand for eco-friendly alternatives that utilize non-toxic materials and recyclable components, which can reduce the overall environmental footprint of thermal coating paper.

Proper disposal and recycling methods are crucial for mitigating the environmental impact of thermal coating paper. Encouraging businesses and consumers to separate these items from regular paper recycling can prevent contamination and promote responsible waste management. Additionally, increasing awareness of the environmental implications accompanying thermal paper usage can spur innovation in developing biodegradable and safer alternatives, paving the way for more sustainable solutions in the paper industry.