Creating Wood Pulp Paper at home can be a rewarding experience. Experts say it’s not as difficult as it seems. Renowned paper artisan, John Smith, once stated, “Homemade Wood Pulp Paper connects us to our resources.” His words highlight the importance of sustainability in this craft.

Making Wood Pulp Paper allows individuals to engage with nature. The process begins with sourcing wood. You can use scraps or even renewable sources like bamboo. This promotes recycling and reduces waste effectively. However, the challenge lies in achieving the right consistency. Learning through trial and error will enhance your skills.

Every step in creating Wood Pulp Paper matters. From boiling the wood to molding the sheets, each action requires attention. It’s easy to overlook small details, yet they significantly impact the final product. Reflections on mistakes will only improve future attempts. The journey of making paper at home invites creativity and dedication. Embrace the process and enjoy your unique creations.

Understanding wood pulp is essential for effective paper making. There are different types of wood pulp: mechanical, chemical, and semichemical.

Mechanical pulp retains lignin, leading to stronger papers but less longevity. Chemical pulp, on the other hand, removes most of the lignin, resulting in smoother and more durable sheets.

According to the International Forest Products Association, over 60% of paper produced globally comes from chemical pulp.

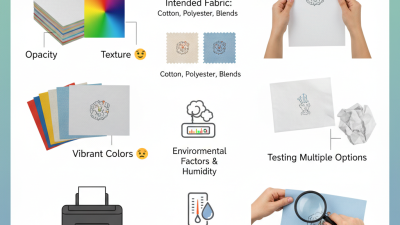

When making paper, choosing the right pulp type matters. Mechanical pulp is often cheaper but can yellow over time.

Chemical pulp offers better quality but might be more costly. Understanding the properties of the pulp you use can drastically affect the output and durability of your paper.

Tips: Always wear protective gear when handling chemicals.

Use a blender or a pulping machine for better consistency in pulp. Experiment with different wood types; each can yield unique textures and strengths.

It’s essential to reflect on the balance between cost and quality.

Some may find that cheaper alternatives lead to disappointing results, requiring further refinement.

To make wood pulp paper at home, you need specific materials and tools. First, gather some wood scraps. Softwoods like pine work well. Hardwoods can be used, but they may produce a denser pulp. You also need water, a blender, and a strainer. These help in breaking down the wood fibers.

Consider adding some recycled paper for better texture. You'll want to collect old newspapers or scrap paper. A large container will be essential for soaking your wood. Look for something that can hold at least a gallon of water. Make sure your workspace is clear and organized. This can prevent accidental spills.

For tools, you’ll need a sturdy screen to form the paper. A sponge can help remove excess water. A rolling pin might assist in pressing the paper down. It’s okay if your first attempts aren't perfect. This process often requires trial and error. You might end up with uneven sheets. Don't be discouraged; refine your method after each batch.

Making wood pulp paper at home is a rewarding task. The process involves converting wood chips into a usable pulp. Start by gathering wooden materials. Small branches or leftover wood work well. Cut the wood into small chips. The smaller the pieces, the easier they will break down. This step is crucial, though it can be tedious.

Next, soak the wood chips in water. Allow them to soak for several hours or overnight. This softens the wood. It can be frustrating if you overlook this part. After soaking, transfer the chips to a pot. Add water and heat it. You need to keep an eye on it. The goal is to soften them enough for pulping. Sometimes, the chips won't dissolve as expected. This can lead to inconsistent results, so adjusting heat is vital.

Once the chips are soft, blend them until you achieve a paste-like consistency. This can be messy, and you may need to clean your equipment afterward. Pour the mixture into a screen or form. Let it drain and dry. You might encounter issues with thickness. Experimenting is part of the process. If the texture isn’t right, trying again is essential. Each attempt teaches you more about creating homemade paper.

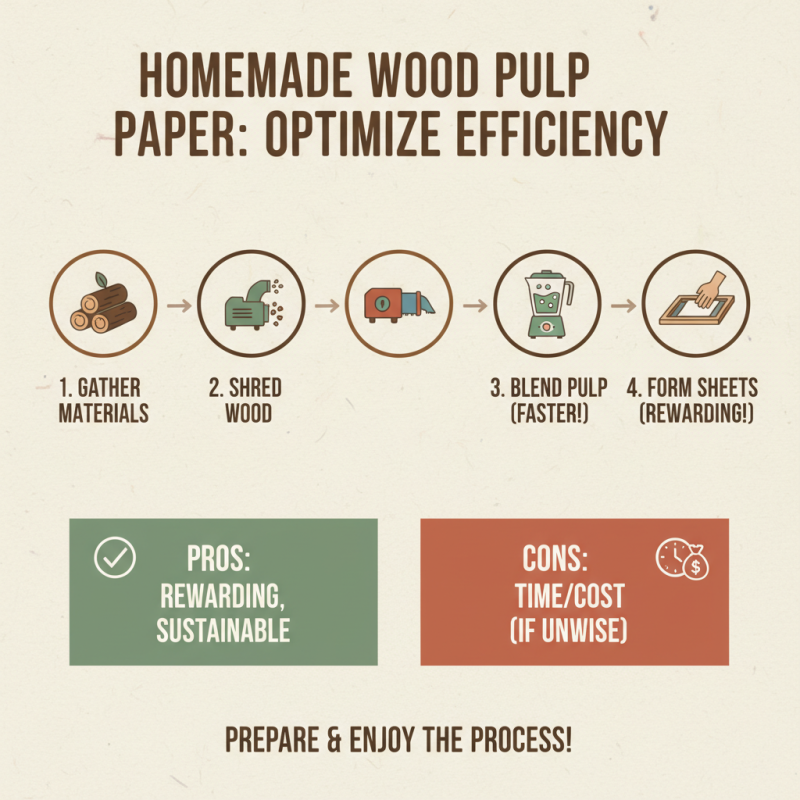

Making wood pulp paper at home can be rewarding. However, the process can be time-consuming and costly if not approached wisely. To optimize efficiency, gather your materials ahead of time. This includes wood, water, and any necessary tools. A blender or food processor can speed up pulp production significantly. Shredding wood into smaller pieces allows for a faster breakdown.

Creating a workspace that is organized is critical. A designated area can help you focus. Keep all tools within reach to avoid wasting time searching for them. Experiment with different wood types; some break down faster than others. This trial and error might slow the process at first, but it yields useful insights.

Using hot water can aid in softening wood more quickly. Soaking wood overnight is helpful but requires planning. Pay attention to how long you leave the wood submerged. Too long can lead to mold or deterioration. Keep an eye on the pulp’s texture as it blends. Achieving the right consistency is essential for quality paper. Reflect on each step and make adjustments based on your observations to enhance efficiency.

Homemade paper production can bring a sense of satisfaction. However, it’s essential to consider its environmental impact. Traditional paper production harms forests and uses large amounts of water. By making paper at home, you reduce waste and promote sustainability.

Using recycled materials is a great start. Old newspapers and cardboard can be transformed into pulp. This process reduces dependency on new wood and lessens pollution. It’s a small step towards eco-friendliness. However, consider the energy used in pulping and drying. Balancing these factors is crucial.

You may encounter challenges while perfecting your method. The consistency of pulp can vary greatly. Sometimes, the final paper can end up too thick or too thin. Experimenting is part of the journey. Reflecting on your techniques will lead to improvement and minimize resource wastage. Embrace the learning process and adjust your practices for better sustainability.

| Step | Materials Needed | Method | Environmental Impact | Sustainability Practices |

|---|---|---|---|---|

| 1 | Wood chips, water, blender, screen | Soak wood chips in water, blend to pulp. | Low impact if sourced sustainably. | Use recycled materials. |

| 2 | Cotton fibers, water, mesh | Mix and blend cotton fibers with water. | Reduces textile waste. | Collect scraps from clothing. |

| 3 | Recycled paper, water, blender | Soak recycled paper and blend. | Minimizes landfill waste. | Prioritize paper sourced from FSC certified sources. |

| 4 | Natural dyes, pulp, water | Add natural dyes during blending. | Sustainable coloring reduces chemical use. | Explore local plant materials for dyes. |

| 5 | Mold, deckle, press | Form sheets and press to dry. | Efficient use of water in the process. | Use solar energy for drying. |