Choosing the right thermal printing paper can greatly impact your printing quality. Experts agree this choice can seem daunting. John Smith, a thermal printing paper specialist, once said, "The right paper makes all the difference in thermal printing." His insight highlights the importance of understanding the features of various types of paper.

There are many factors to consider when selecting thermal printing paper. The weight and texture can affect print clarity. Different applications may require specific characteristics. For example, paper meant for labels should be durable and smudge-resistant. A mismatch can lead to less than ideal results, impacting business operations and customer satisfaction.

Moreover, not all thermal printing papers are created equally. Some may not perform well under certain conditions. Assessing the environmental factors affecting the paper can be tricky. It's essential to find a balance between cost and quality. Paper that saves money upfront can sometimes lead to high costs later. Therefore, a thoughtful choice in thermal printing paper is crucial for lasting effectiveness.

When selecting thermal printing paper, it's essential to understand the various types available in the market. Thermal paper generally falls into two categories: direct thermal and thermal transfer. Direct thermal paper uses heat-sensitive coatings to produce images. This type tends to fade over time when exposed to heat or sunlight. Users often overlook this, leading to lost information.

On the other hand, thermal transfer paper requires a ribbon to transfer ink onto the paper. This method is more durable, producing clear images that resist fading. However, finding the right ribbon for compatibility can be tricky. It's common for users to choose the wrong type, causing frustration and waste.

Different environments may also affect paper choices. For example, high humidity can damage thermal paper. In indoor settings, this might not be a problem, but outdoor use can present challenges. Make sure to consider where you’ll use the printed materials. The wrong decision can lead to unexpected results, creating additional costs and delays. Reflecting on the specific needs of your printing tasks is crucial for making informed choices.

| Paper Type | Thickness (microns) | Sensitivity | Image Quality | Application |

|---|---|---|---|---|

| Thermal Paper | 50-75 | High | Excellent | Receipts, Labels |

| Direct Thermal | 60-80 | Medium | Good | Shipping Labels |

| Carbonless Thermal | 70-90 | Low | Fair | Multi-part Forms |

| Synthetic Thermal | 80-100 | Very High | Excellent | Durable Labels |

| High-Temperature Thermal | 50-80 | Medium | High | Industrial Use |

Choosing the right thermal printing paper involves several key factors. One important aspect to consider is the paper's sensitivity to heat. High sensitivity ensures clearer prints, while low sensitivity may lead to faded or illegible text over time. It can be useful to examine print quality in varying temperatures. Experimenting with different papers may yield surprising results.

Another factor is the paper's thickness. Thicker paper often produces durable prints, which can withstand handling. However, this can also affect the printer's feeding mechanism. Sometimes, printers struggle with papers that are too thick. Therefore, it is important to test various weights to find a suitable balance.

Lastly, think about the intended use of the printed material. If the prints need to be archived or stored, consider selecting paper that is resistant to fading and damage. In contrast, if the prints are temporary or for short-term use, this may not be a priority. Reflecting on these needs helps in making a more informed choice, even if the path isn’t always clear.

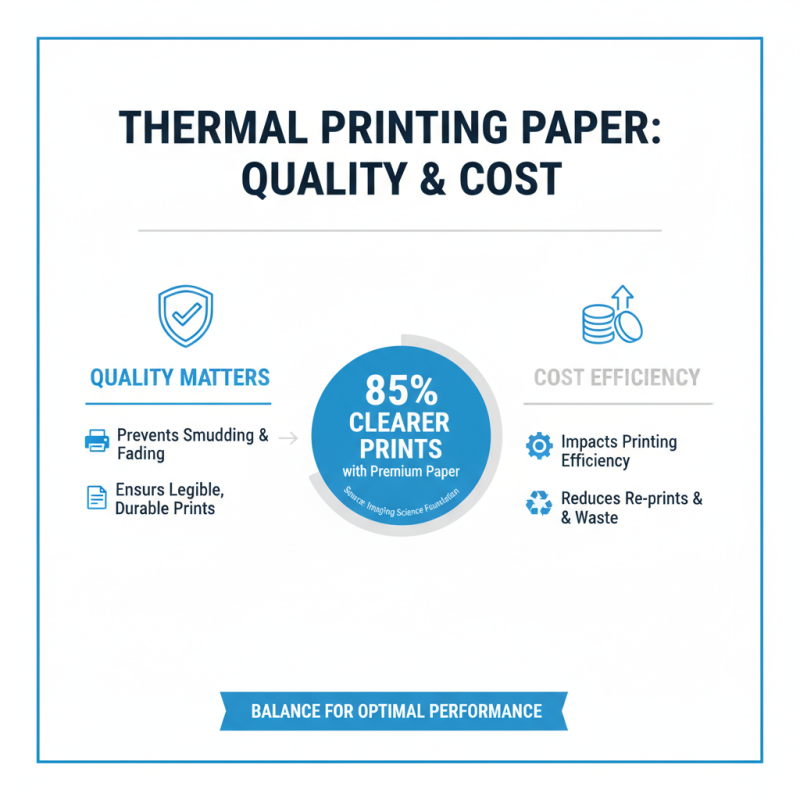

When selecting thermal printing paper, both quality and cost are crucial. Thermal printing paper quality can significantly impact printing efficiency and durability. High-quality paper prevents smudging and fading, ensuring legible prints. A study from the Imaging Science Foundation indicates that 85% of businesses report clearer prints with premium paper.

Cost is another factor to consider. Budget options may save money upfront but might lead to higher long-term expenses. A report by the Paper and Imaging Manufacturers Association revealed that cheaper paper can wear down printers faster. This ultimately leads to increased maintenance costs.

Choosing the right paper involves balancing quality and price. Lower quality papers can be tempting, but they might result in waste. Users often overlook the hidden costs associated with poor-quality materials. Failing to account for printer damage or frequent reprints undermines the initial savings. It’s essential to analyze overall costs for the best long-term decision.

When selecting thermal printing paper, compatibility with your printer is crucial. Different printers require specific types of paper. Not all thermal papers work seamlessly with every printer model. It is essential to check your printer’s specifications before making a purchase. For example, the width and type of thermal paper can greatly influence print quality.

Look for details in the printer manual regarding acceptable paper types. Some printers may require coated thermal paper, while others function better with uncoated options. Measuring the roll size is also vital. An incorrect width can lead to misalignment during printing. If the paper is too thick, it might jam the printer.

Testing different paper types is also key. Sometimes, even when the specs match, the print quality can differ. A paper that seems perfect may not produce accurate colors or clear images. It can be frustrating to install new paper only to find it leads to smudging or fading. Be prepared to experiment a bit. This process can be enlightening, revealing more about what your equipment truly needs.

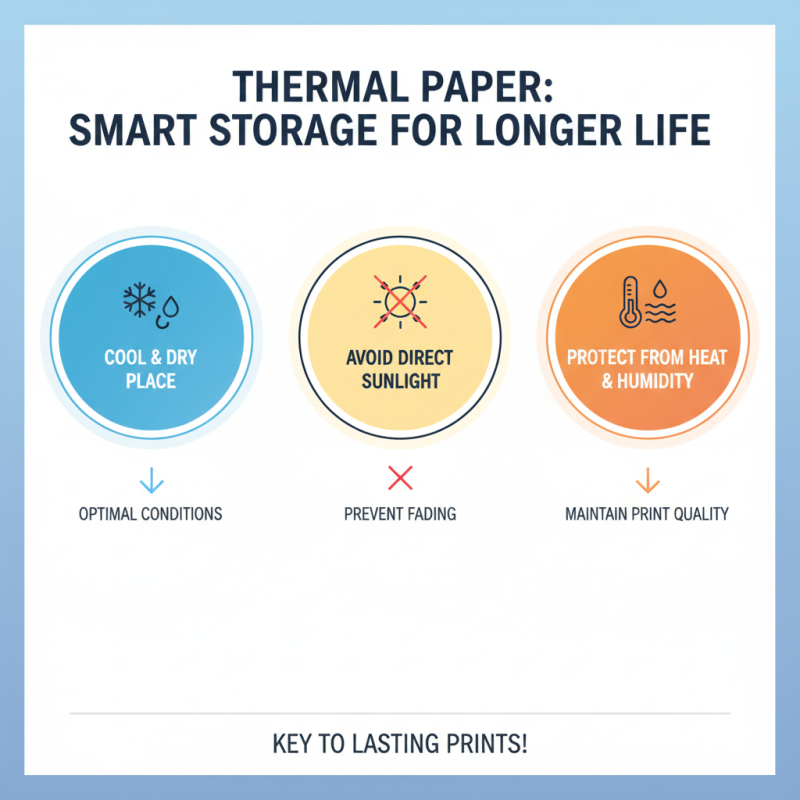

Proper storage and handling of thermal printing paper can enhance its lifespan. Keep thermal paper in a cool, dry place. Avoid exposure to direct sunlight. High temperatures and humidity can damage the paper. It's easy to overlook these details, but they are crucial for maintaining print quality.

When handling thermal paper, avoid touching the print side. Fingerprints can cause smudging and reduce clarity. Use clean hands or gloves to prevent oils from transferring. It's easily forgotten, yet necessary for the best results. Don't stack heavy items on top of the paper, as this can cause creases or damage.

Be mindful of the expiration date on your thermal rolls. Using outdated paper may lead to faded prints. Proper rotation of stock can help prevent issues. Some might neglect checking these dates, resulting in poor printing. Always label your storage containers for easy access. This small step can save time and frustration when you need paper quickly. It's the little details that make a difference.