When it comes to choosing the best thermal papers for your needs, expert opinions matter. Jane Smith, a leading authority in the thermal paper industry, emphasizes, "Selecting the right thermal paper can make or break your printing experience." This highlights how crucial it is to understand the different types of thermal papers available.

Thermal papers vary widely in quality and function. Some are designed for high-speed printers, while others work best with lower-speed models. The choice depends on your specific requirements. For example, food industries often require paper that withstands temperature changes. Retail businesses need paper that is quick to print and durable enough for receipts.

Choosing thermal papers can be more complicated than it seems. It involves analyzing your workload and printing speed. You might feel limited by options, leading to choices that don’t entirely meet your needs. It’s essential to weigh the quality against the cost. Thus, making an informed decision calls for careful consideration and self-reflection on what is most important for your operations.

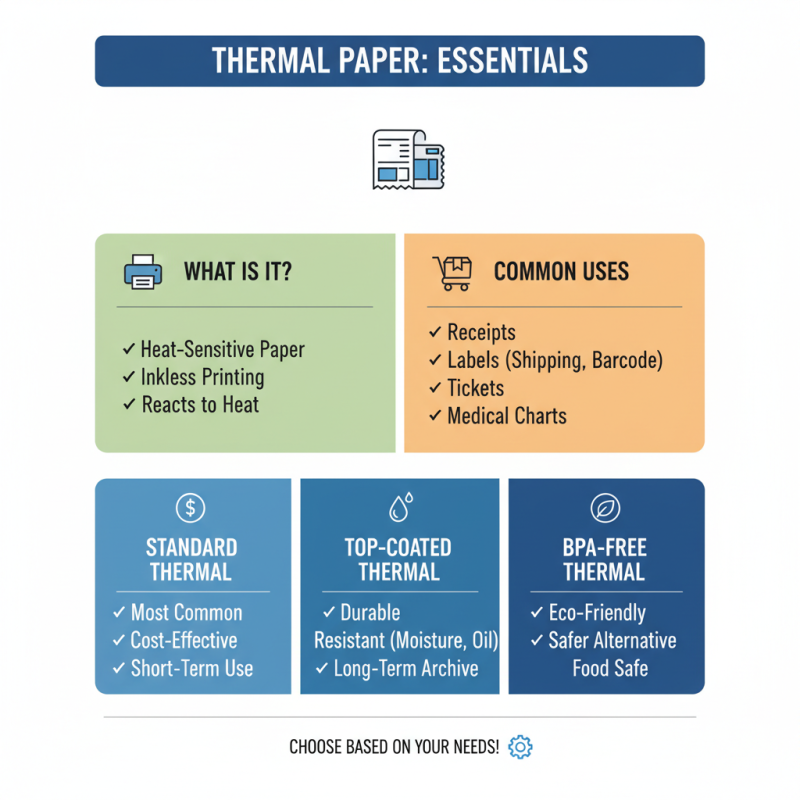

Thermal paper is essential for various applications, including printing receipts and labels. Choosing the right type depends on your specific needs. There are different types of thermal paper available in the market, each with unique characteristics.

One common type is direct thermal paper, which is sensitive to heat. This paper is ideal for short-term applications because it can fade over time. Another type is thermal transfer paper, which requires a ribbon to print. It is more durable and suitable for long-lasting prints. Understanding these differences helps in making an informed decision.

When selecting thermal paper, consider the print quality you require. A higher sensitivity often means better quality, but it may also lead to faster fading. Think about your usage environment. Will the print be exposed to heat or moisture? These factors significantly impact paper performance.

**Tip:** Always test samples before purchasing in bulk. This will save you time and ensure the quality meets your requirements.

**Tip:** Store thermal papers in a cool, dry place. Excessive heat or humidity can affect their quality.

Understanding these paper types will guide you in making the best choice for your needs.

When selecting thermal paper, several key specifications come into play. The thickness of the paper is crucial. Thicker paper often means better durability and print quality. Check the weight, typically measured in grams per square meter (GSM). A weight between 50-80 GSM is common for general use. Consider how often you will use it. Frequent usage demands more robust options.

Another importante specification is the roll size. Standard widths range from 57mm to 80mm. Ensure it fits your device. The length of the roll also varies. Longer rolls reduce the frequency of replacements. It's essential to balance size with storage capabilities. High humidity environments may require specific coatings to prevent fading.

Finally, keep in mind the type of printing technology. Different thermal papers perform better with different printers. Not all papers are compatible with all devices. This oversight can lead to frustrating experiences. Testing a small batch before settling on a purchase is wise. Mistakes in selection can result in wasted resources and time. Make sure to evaluate the quality of print and durability under your specific conditions.

Coating plays a vital role in the performance and durability of thermal papers. The coating determines how well the paper retains its printed information. A good coating offers resistance to smudging and fading. This ensures that prints remain clear and legible over time. However, not all coatings are created equally. Some may wear off quickly, especially in harsh environments.

Consider the conditions where the paper will be used. For outdoor use, coatings that resist moisture and UV light are essential. In contrast, indoor applications might require less resilient options. A balance between durability and print quality is crucial. Thick coatings can enhance durability, but they may also impact the brightness and texture of the paper. This trade-off can lead to unexpected results in printing quality.

Testing thermal paper is important. Sometimes, the performance varies between batches. It’s wise to request samples before committing to larger orders. Also, examine how the paper interacts with different printing technologies. Observing how well it holds up in varied conditions can reveal potential issues. By closely evaluating the coating's properties, users can make better-informed choices for their specific needs.

When assessing the cost-efficiency of thermal papers, comparing various brands becomes crucial. Prices can vary significantly depending on the manufacturer. Some offer lower prices but compromise on quality. This can lead to faded prints and increased reprints, driving up overall costs.

It’s essential to evaluate the price per roll and the number of sheets it contains. A pack may seem cheap at first glance. However, if it doesn’t perform well, you’ll end up spending more. Look for customer reviews. Authentic feedback can reveal issues like smudging or paper jams that you wouldn’t notice in a quick glance.

Experimenting with various options can be helpful, but it’s often frustrating. You might find a less expensive brand only to be disappointed later. Tracking your expenses and identifying patterns in usage can provide better insights. It helps in making informed decisions that could save you money in the long run. Every choice has its pros and cons, and careful consideration is key.

When selecting thermal papers, understanding industry standards and certifications is crucial. Thermal papers vary significantly in quality and functionality, and adhering to recognized benchmarks can help ensure reliability. The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide guidelines for thermal paper specifications. Papers that meet ISO 9001 certification reflect consistent quality management practices. Reliable thermal paper typically shows resistance to fading, which is essential for long-lasting prints.

Tip: Always check for certifications. Investing in certified thermal paper can save time and money in the long run. Beware, not all papers claiming to be “thermal” are created equal. Conduct thorough research to avoid low-quality products that don’t meet your application needs.

Moreover, environmental standards are also important. Look for papers marked as eco-friendly or recyclable. Recent studies indicate that sustainable thermal papers can reduce environmental impact without compromising performance. Yet, some of these options may offer lower thermal sensitivity. This can lead to slower printing speeds and decreased print quality. Consider these aspects when making a choice. Prioritize your operational needs while being mindful of environmental factors.