Choosing the right A3 Wood Pulp Paper is crucial for optimizing print quality and efficiency. In an industry where the demand for high-quality printing materials continues to rise—expected to reach a market value of $12 billion by 2025—it becomes imperative for businesses and individuals to make informed decisions. According to a recent report by Smithers Pira, A3 Wood Pulp Paper is favored for its superior brightness and print clarity, making it an essential choice for professional print jobs and commercial applications.

Industry expert Dr. Lisa Tran emphasizes the significance of selecting the appropriate paper for achieving desired results. She notes, "The selection of A3 Wood Pulp Paper not only affects print quality but also influences the overall sustainability of the printing process." Given the environmental concerns surrounding paper production, understanding the characteristics of A3 Wood Pulp Paper—including its fiber source and processing methods—can guide users toward more sustainable choices.

In this guide, we will explore various factors to consider when selecting A3 Wood Pulp Paper for your printing needs, from weight and texture to environmental certifications. By understanding these elements, you can ensure your printing projects not only look professional but also align with sustainable practices.

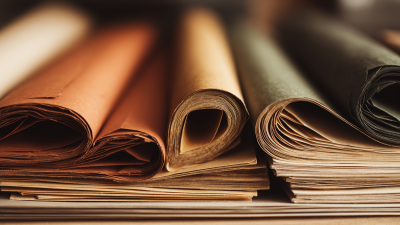

When selecting the best A3 wood pulp paper for printing needs, it is essential to understand the key characteristics and types available. A3 wood pulp papers are typically derived from sustainable sources, providing a reliable choice for various printing applications. These papers are available in different finishes, such as glossy, matte, and textured, each catering to specific printing techniques and desired outcomes. Glossy finishes, for instance, enhance color vibrancy, making them ideal for photographs and high-quality visual prints. In contrast, matte finishes reduce glare and are preferred for text-heavy documents.

Another vital consideration is the weight and thickness of the A3 wood pulp paper. Paper weight is measured in grams per square meter (GSM), with heavier papers generally providing a more premium feel and greater durability. Additionally, factors such as brightness and opacity should be evaluated, as they influence print clarity and the overall impression of the final product. By familiarizing oneself with these traits, consumers can make informed decisions that align with their printing objectives and enhance the quality of their printed materials.

| Characteristic | Type A | Type B | Type C |

|---|---|---|---|

| Thickness (g/m²) | 80 | 100 | 120 |

| Brightness (%) | 90 | 92 | 94 |

| Opacity (%) | 85 | 88 | 90 |

| Texture | Smooth | Satin | Textured |

| Print Quality | Standard | High | Premium |

| Price Range (USD) | 0.05 - 0.10 | 0.10 - 0.15 | 0.15 - 0.20 |

When selecting A3 wood pulp paper for printing, evaluating paper weight and thickness is crucial for achieving optimal results. Paper weight, measured in grams per square meter (GSM), corresponds to the density and sturdiness of the paper. Common weights for A3 paper range from 70 GSM for everyday printing to 300 GSM for high-quality graphics and professional presentations. For typical office tasks, 80-100 GSM paper strikes the right balance between durability and affordability, ensuring that documents feel substantial without overly taxing your printer.

Thickness, often indicated in microns, plays a significant role in how printing ink interacts with the paper surface. Thicker paper can absorb more ink without warping, which is particularly beneficial for photo printing or designs requiring sharp details. Conversely, thinner paper may lead to ink bleed and less vibrant images. When choosing A3 wood pulp paper, consider the intended use; for high-resolution images and marketing materials, a thicker paper around 200-300 microns is preferable, while regular text documents can comfortably use thinner options. Understanding these specifications will help you tailor your paper choice to meet your specific printing needs effectively.

When selecting A3 wood pulp paper, one key consideration is the finish: glossy or matte. Each finish offers distinct advantages that can significantly affect the final appearance of your printed materials. According to a report by Smithers Pira, prints on glossy paper can have a brightness level up to 20% higher than those on matte finishes, resulting in more vibrant colors and sharper images. This makes glossy paper ideal for high-impact visuals, such as brochures and advertisements, where the goal is to catch the viewer's eye.

On the other hand, matte finishes bring a subtle, sophisticated feel to printed materials. Research from Neenah Paper shows that matte papers reduce glare, making them a better choice for readability, especially in documents like reports or menus. Additionally, matte paper tends to be more resistant to fingerprints and smudges, which can be beneficial for items that may be handled frequently. Ultimately, the choice between glossy and matte A3 wood pulp paper should align with the purpose of the printed piece, keeping in mind factors such as intended audience engagement and the desired aesthetic quality.

When selecting A3 wood pulp paper for printing, understanding compatibility with different printing techniques is crucial. Inkjet printers generally require paper with a specific coating to ensure that the ink dries quickly and does not smear. According to a report from the Paper and Paperboard Packaging Environmental Council, around 65% of households in the U.S. use inkjet printers, making it essential for paper manufacturers to produce high-quality options that optimize ink absorption. Look for A3 wood pulp papers with a smooth finish, which can enhance image clarity and color vibrancy.

On the other hand, laser printers utilize heat to fuse toner onto the paper, which means that the paper must be able to withstand higher temperatures without curling or warping. A study by the International Association of Printing Technologies highlights that approximately 35% of print jobs are done using laser technology. Therefore, when selecting A3 wood pulp paper, ensure it is labeled as "laser compatible," which often indicates it has higher moisture resistance and better dimensional stability. Understanding these differences can lead to enhanced print quality and a more successful outcome for printed materials.

When selecting A3 wood pulp paper for printing, sustainability considerations play a crucial role in making eco-conscious choices. With increasing environmental concerns, many manufacturers now offer papers that are not only high-quality but also sourced from sustainable practices. Look for products that are certified by organizations like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications indicate that the wood pulp used in the paper is harvested responsibly, ensuring that forests are managed in a way that preserves biodiversity and supports local communities.

Additionally, consider the paper’s composition. Opt for papers made from recycled materials, which significantly reduce the demand for virgin wood pulp. Recycled A3 paper retains quality comparable to non-recycled counterparts while minimizing the carbon footprint associated with production. Furthermore, some brands offer chlorine-free bleaching processes, resulting in a less harmful impact on waterways and ecosystems. By focusing on these eco-friendly options, you can meet your printing needs while contributing to a more sustainable future.